M2

Enhance your optical comparator and measuring microscope experience through intelligent, touch enabled windows software design.

Product Features

-

Clean, Intuitive Design

The user interface design of the M2 software means you’ll spend more time measuring and less time reading manuals. By combining a familiar user experience with current touch screen conventions, the M2 software can quickly be integrated into your process and accessible to a wide range of users.

-

Advanced crosshair probe toolbox

For Optical Edge enabled systems, both “simple” and “auto edge” crosshair probes are available. The “auto edge” probe captures points on edges automatically upon crossing. The M2’s EdgeLogic™ system (Optical Edge enabled systems only) enables gesture driven control of start and end measurement commands. Start and finish measurements quickly, without the need for direct software interaction.

-

Support for Optical Edge or Cross hair measuring systems

Gain access to many of the same powerful features, and intuitive measuring environment, whether using an optical edge equipped system or an externally generated cross hair device. Precise optical edge detection mechanisms provide accurate results as well as access to powerful, industry first, measurement functionality.

-

Designed for Multi-Touch software control

In addition to the conventional mouse interface, expanded Multi-Touch logic allows for versatile pan and zoom of the active part view. Increase the efficiency of feature construction, feature data manipulation, and reporting tasks with a simple pinch zoom, swipe pan, or double click.

-

Advanced crosshair probe toolbox

For Optical Edge enabled systems, both “simple” and “auto edge” crosshair probes are available. The “auto edge” probe captures points on edges automatically upon crossing. The M2’s EdgeLogic™ system (Optical Edge enabled systems only) enables gesture driven control of start and end measurement commands. Start and finish measurements quickly, without the need for direct software interaction.

-

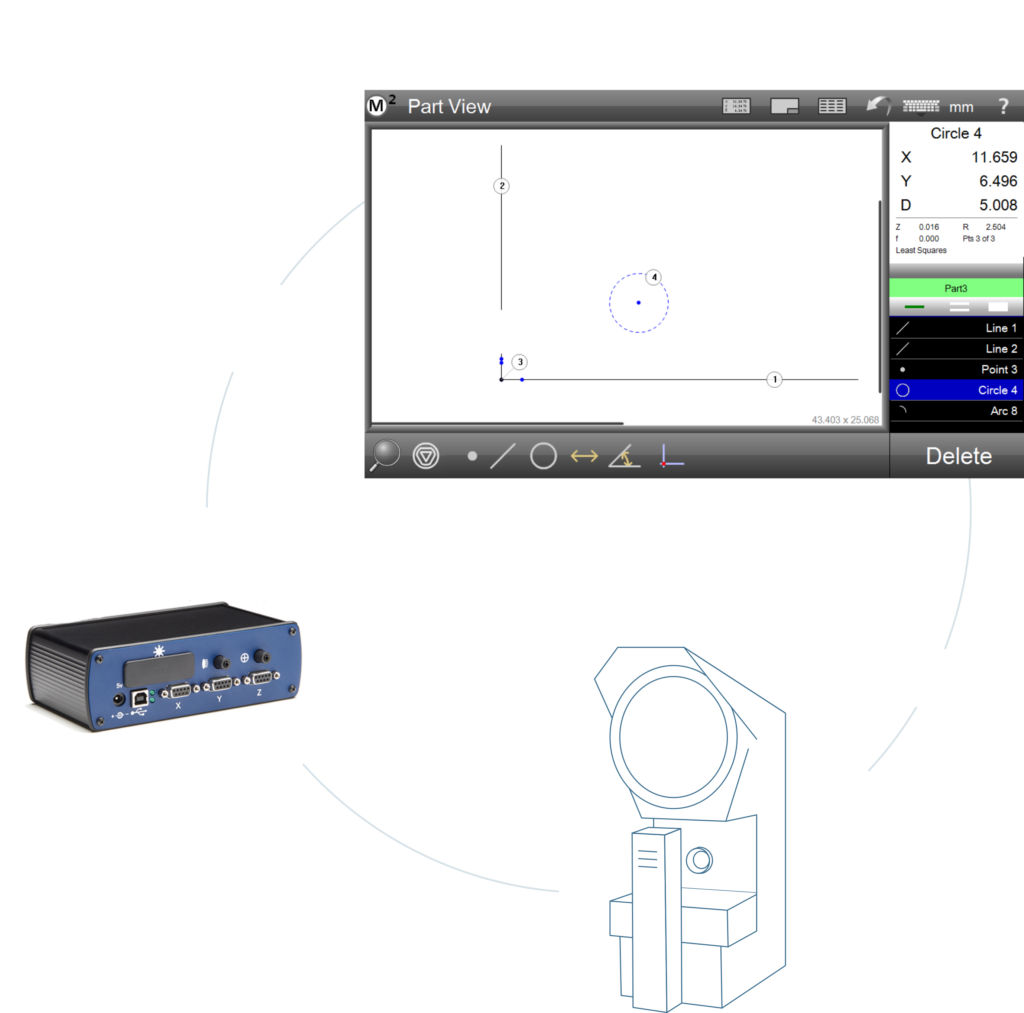

Graphics-based “Part View” constructions

Generate popular construction types, like Distances and Tangent Lines, from within the graphical part view itself. Constructions with multiple sub-types can be toggled quickly with the change feature type command.

Supported construction types include:

- Average

- Intersections

- Tangent Line(s)

- Angle Compliments

- Offset Skew Lines

- Mid/Center Point(s)

- Shortest Distance

- Gage Circle(s)

- Perpendicular/Parallel Line(s)

- End Point(s)

- Farthest Distance

- Bolt Circle

-

Feature Detail Graphics

Individual feature views provide informative drawings displaying point cloud distributions, as well as nominal deviations, and tolerance results. Scroll through your measured features list from this view for a feature by feature display of Actual, Nominal, Tolerance, and Deviation results. Set the desired data fit type from the “Actual” screen using the “fit toggle” button.

-

Geometric tolerancing

You may measure features, set nominals, apply tolerances and view deviation results with only a few quick clicks. You may also apply a variety of popular tolerance types to features in the standard “feature-to-feature” fashion, or utilize the “place tolerancing” system for applications where tolerances are specified in a block tolerance style call out. For these cases the M2 software let’s you enter and apply universal tolerance values according to your feature resolution groupings.

Supported tolerances include:

- X/Y/Z Positional

- Diameter/Radius/Length/Width Size

- Theta (Angle)

- Form

- Parallelism

- Angularity

- True Position (LMC/MMC Modifiers)

- Straightness

- Perpendicularity

- Roundness

- Concentricity

- Runout

-

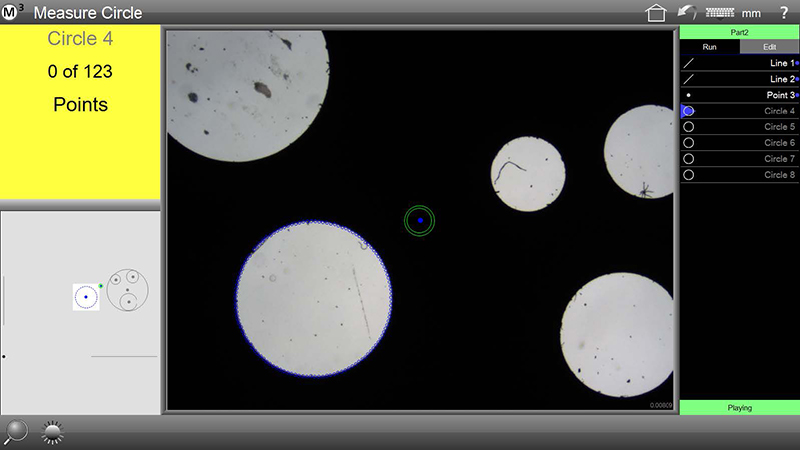

Part programs and playback

Playback or edit groups of measured, constructed, and created features from a saved part program file. Part program files, when loaded, will prepare the M2 software to repeat a sequence of feature measurement steps, printed reports, and exported measurement data. The playback guidance mechanism provides helpful on-screen instruction for successful playback of your part programs.

-

Reports

Flexibility for report contents and formatting allows for full customization of the data format, header information, and header and footer graphics.

Report data formats include:

- Standard Report

- Tolerance

- CSV

- European

-

Machine Integration

Ask your MetLogix representative about a wide variety of encoder interface technologies, camera types, and light control hardware supported in the M3 system.

-

Support for all current industry standard software methodologies for Stage and Camera calibration

Robust and reliable machine/camera calibration can be achieved using popular machine and video correction methods. Linear Error Correction (LEC), Segmented Linear Correction (SLEC), Non-Linear Error Correction (NLEC), Orthogonality, Pixel Size, Camera Skew, Parcentricity, and Field of View).

-

Industry leading Operating System platform

The Windows® 10 operating system represents the current enterprise solution for computer software operating systems. You gain the performance and reliability of a globally recognized software solution as part of you measuring machine package. The largest compatibility platform for printers and data management software makes data handling tasks simple and flexible.

Common Machine Types

Optical Comparator