The new M3 Version 4 is now available! Read below about the powerful new functionality that has been added to the M3 Measuring Software.

-64 Bit Support

The M3 v4.00.00 marks the move from a 32bit application to a 64bit application

- Access to additional available PC system memory(RAM).

- Faster management of large part programs.

- Support for larger stitched images.

- Faster processing of large DXF files.

- Current with the file systems of modern PC and Windows applications.

-Save/Load Reference Frame Files

- Save reference frames to, and load references frames from, an external file.

- Utilize ref frame files to support the use of part fixtures across multiple programs and multiple machines.

- Ref frame files update both coordinate system and registration information in the software.

-Expanded 3D Feature Support

- Distances constructed between 3D features will now default to 3D type. Distances between 2D/Projected features can be changed to a 3D distance type.

- 3D distances can be Perpendicular Center to Center, or Nearest Surface.

- 3D line information can now be generated via the new “Axis” feature type.

- The new “Axis” feature will contain Phi, XY/YZ/ZX coefficients for its 3D position and orientation.

-Enhanced Program Recording Mode

- Author part programs explicitly using the new Advanced Record Mode button.

- Feature measurement steps, will be displayed in the program list as they are recorded, including goto moves, light control steps, message steps, etc..

- Full access to program editing functions while recording part programs.

-Probe and Goto Path Editing

- New goto and probe path view in the M3 partview.

- Edit touch probe points and goto positions using the new editing dialog.

- Use single step mode to move through complex part programs one step at a time.

-Near/Far VED Probe

- A new Near/Far video probe can be added to the V4 probe menu.

- The “buffer style” probe creates a rectangular region where the nearest and furthest point within the region can be probed.

- Using the “skew lock” mode for the probe allows for locking the probes scan orientation to the current part alignment.

-Color/Contrast Image Process Controls

- Two new image processing functions have been added to the V4.

- A color filter allows for the separation of equally bright, but different color regions of a part.

- A contrast/binarize filter has been added to allow for the increase or decrease of contrast in an image.

- Images under IP control will be converted to greyscale.

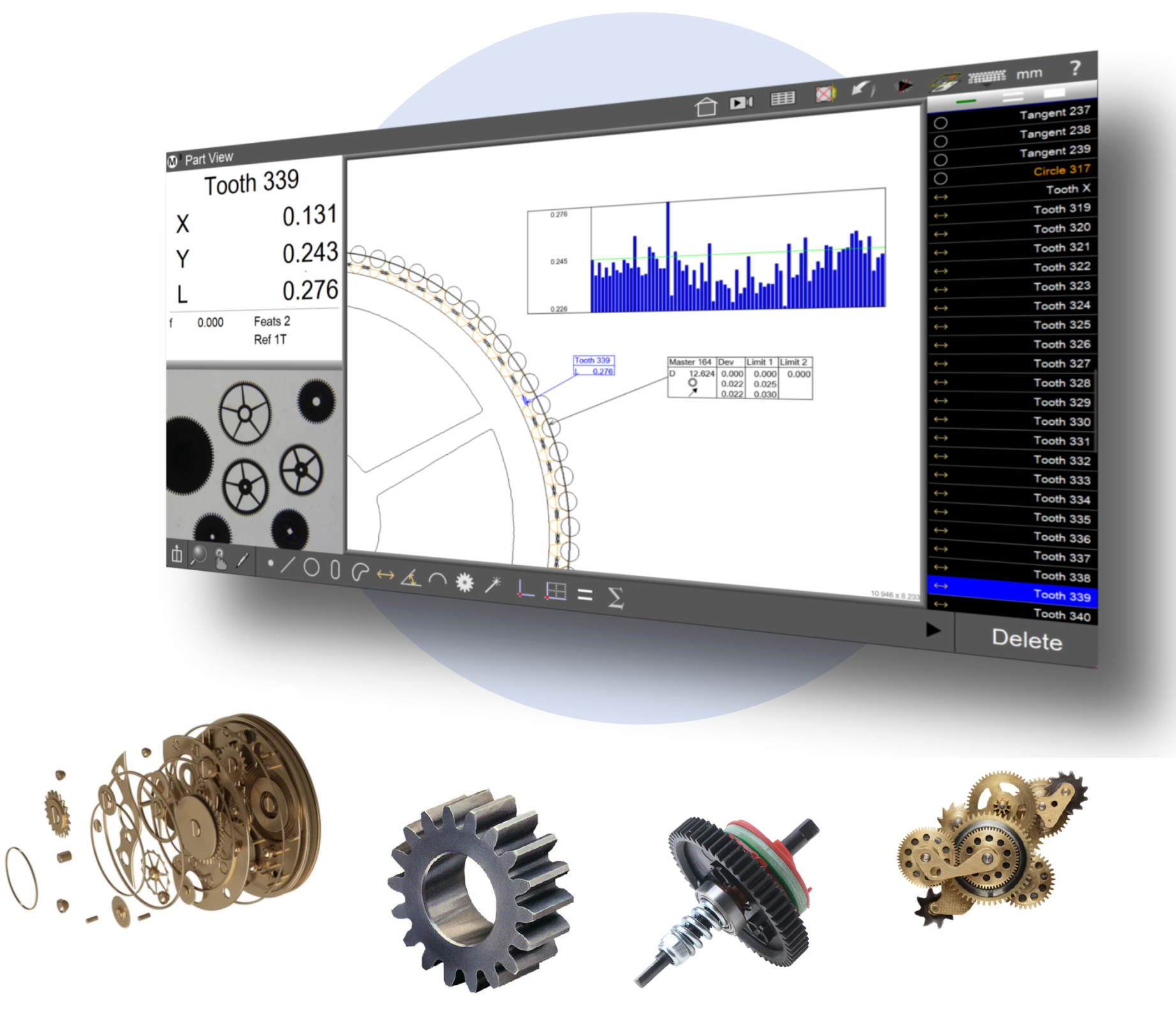

-Profile Fit from Alternate Point Sources

Three new profile enhancements have been introduced in V4.

- 1) Probed features in the M3 can now be used as point sources for a profile fit.

- 2) Previously fit profiles can now be “combined/refit” into a new single profile fit result.

- 3) Profile fitting is now supported in optical comparator systems.